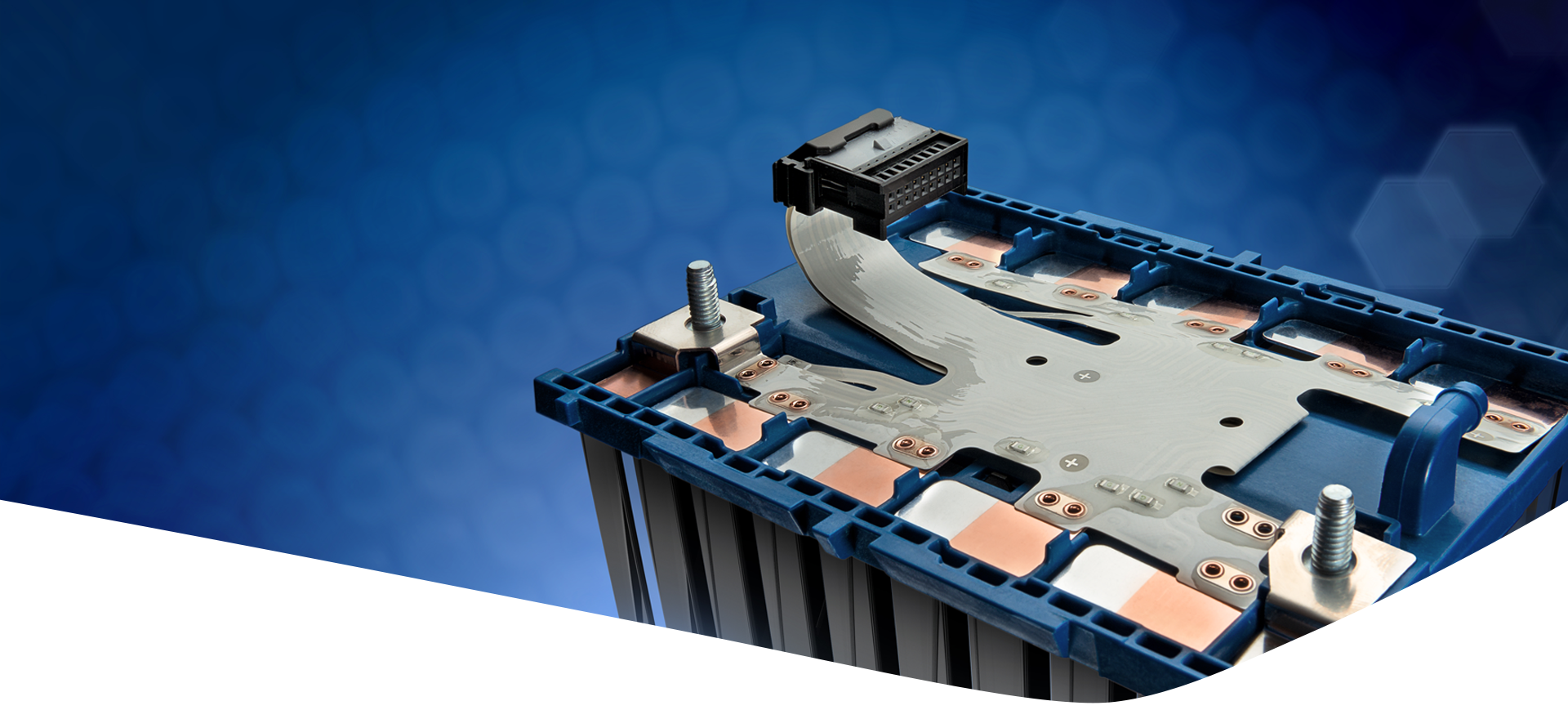

Technologies For Every Battery Cell Type

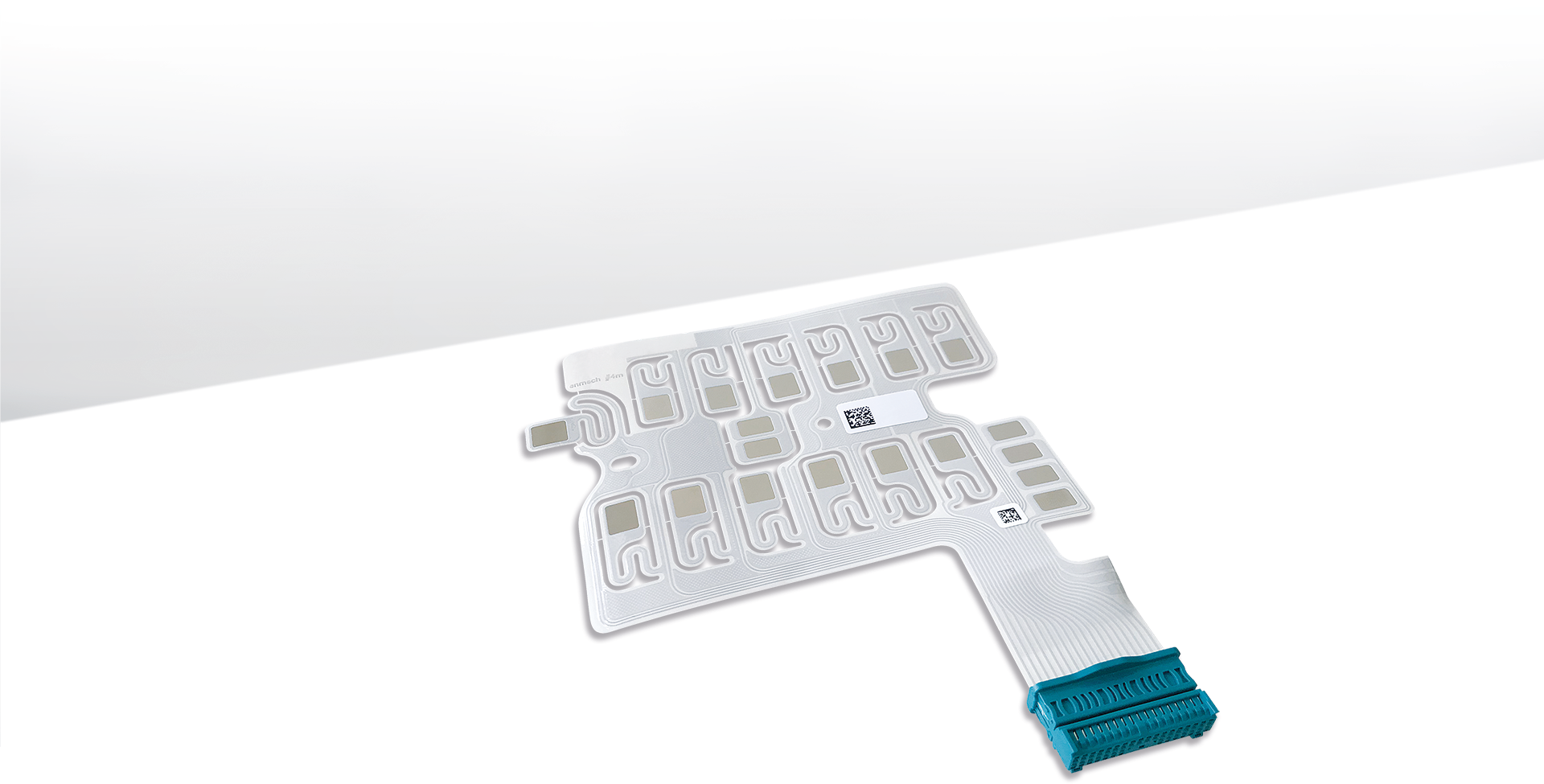

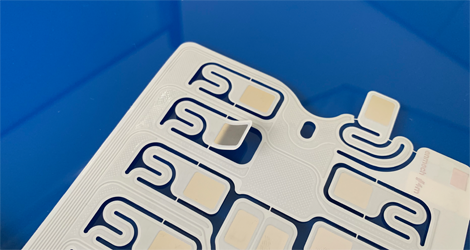

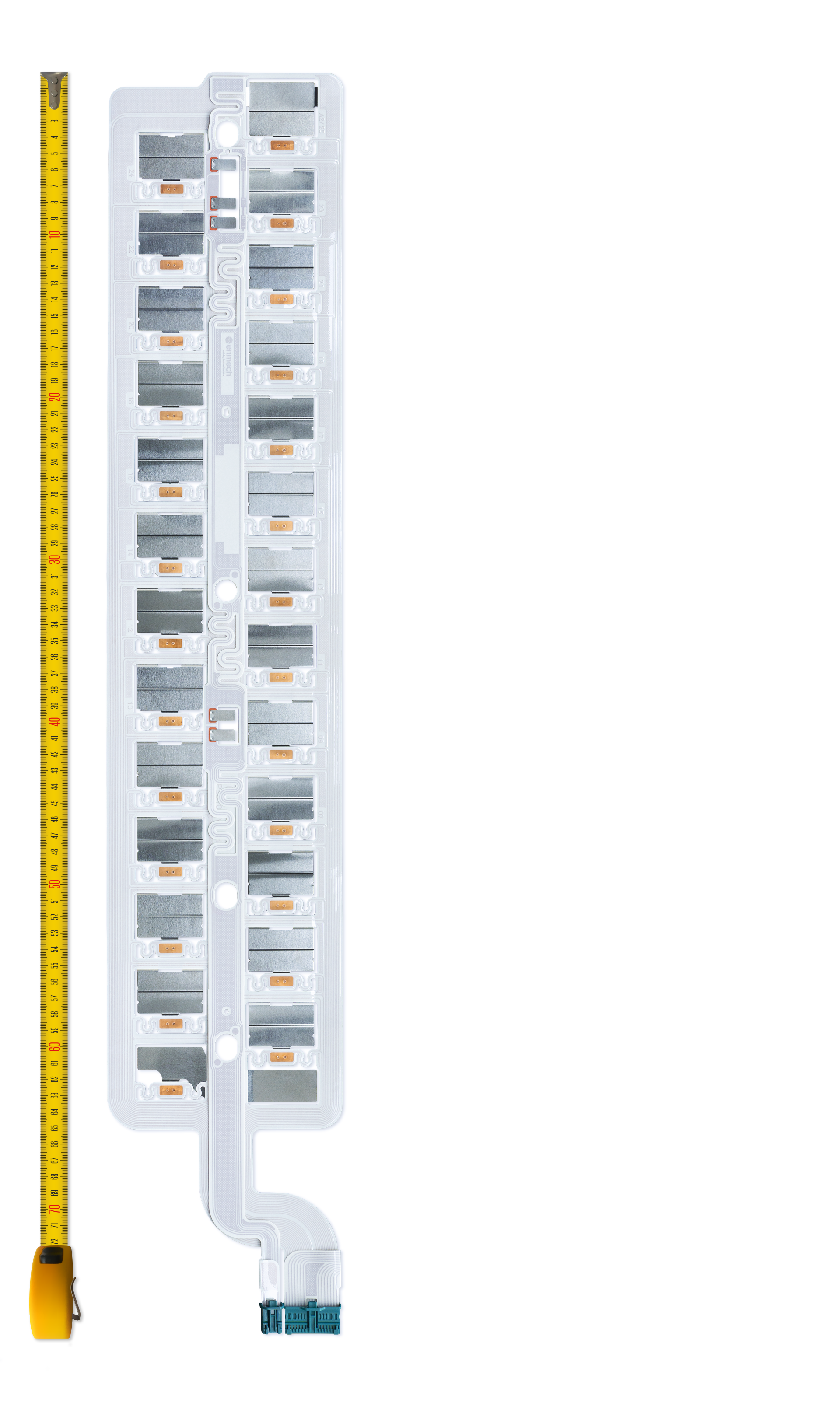

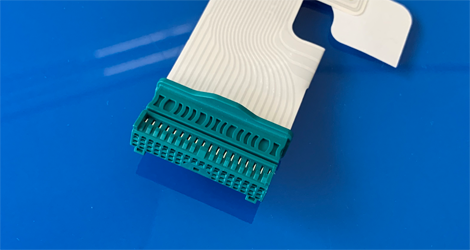

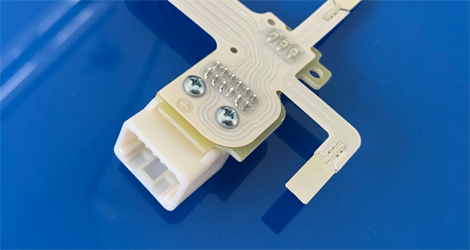

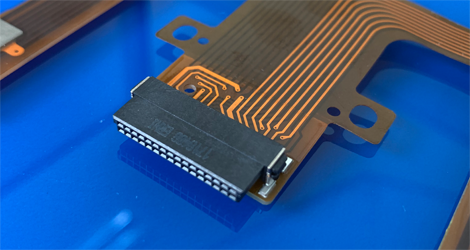

Varying material combinations and different cell designs characterize high-voltage cell interfaces. Mektec interconnection technologies, welding and riveting, offer a reliable and proven solution for every design. Please have a look: