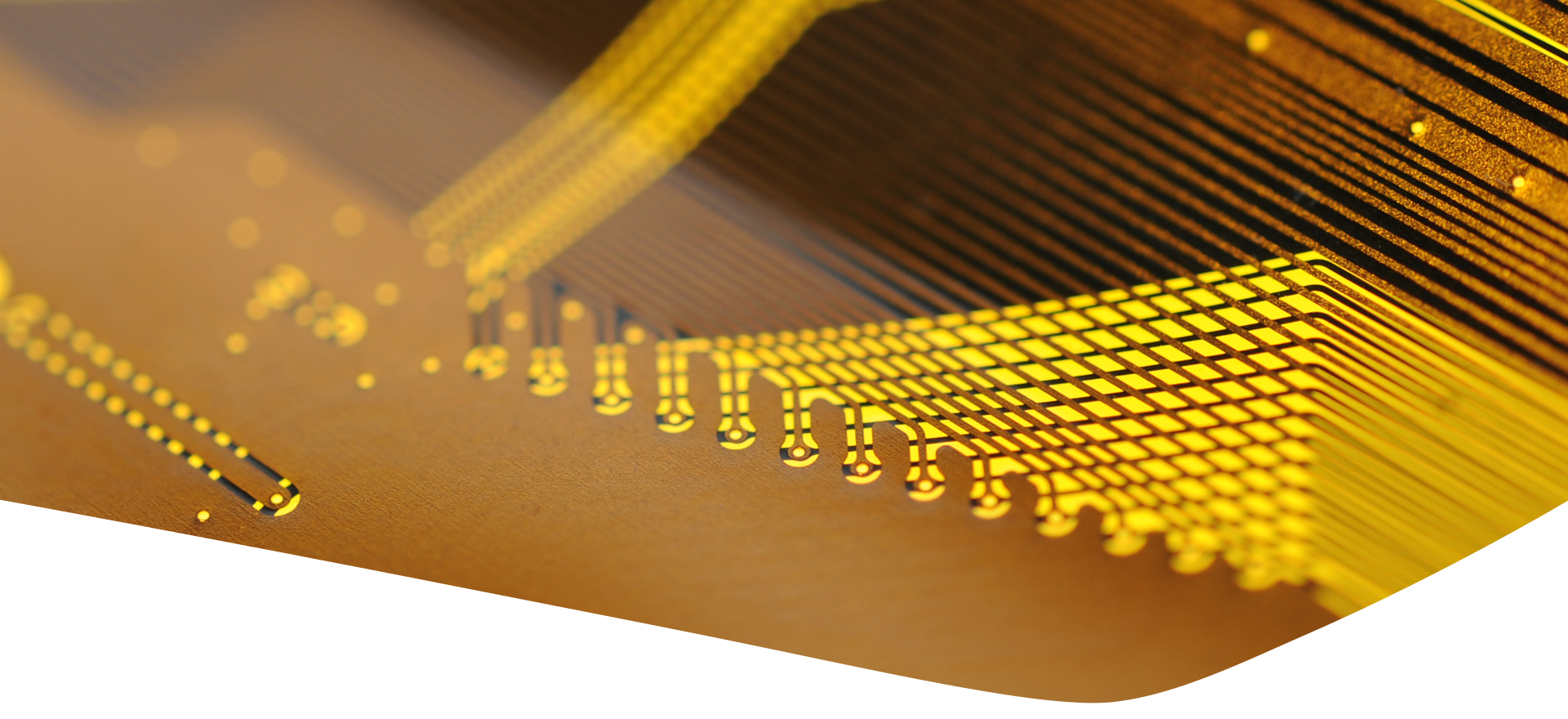

Ultra-miniaturized Precision

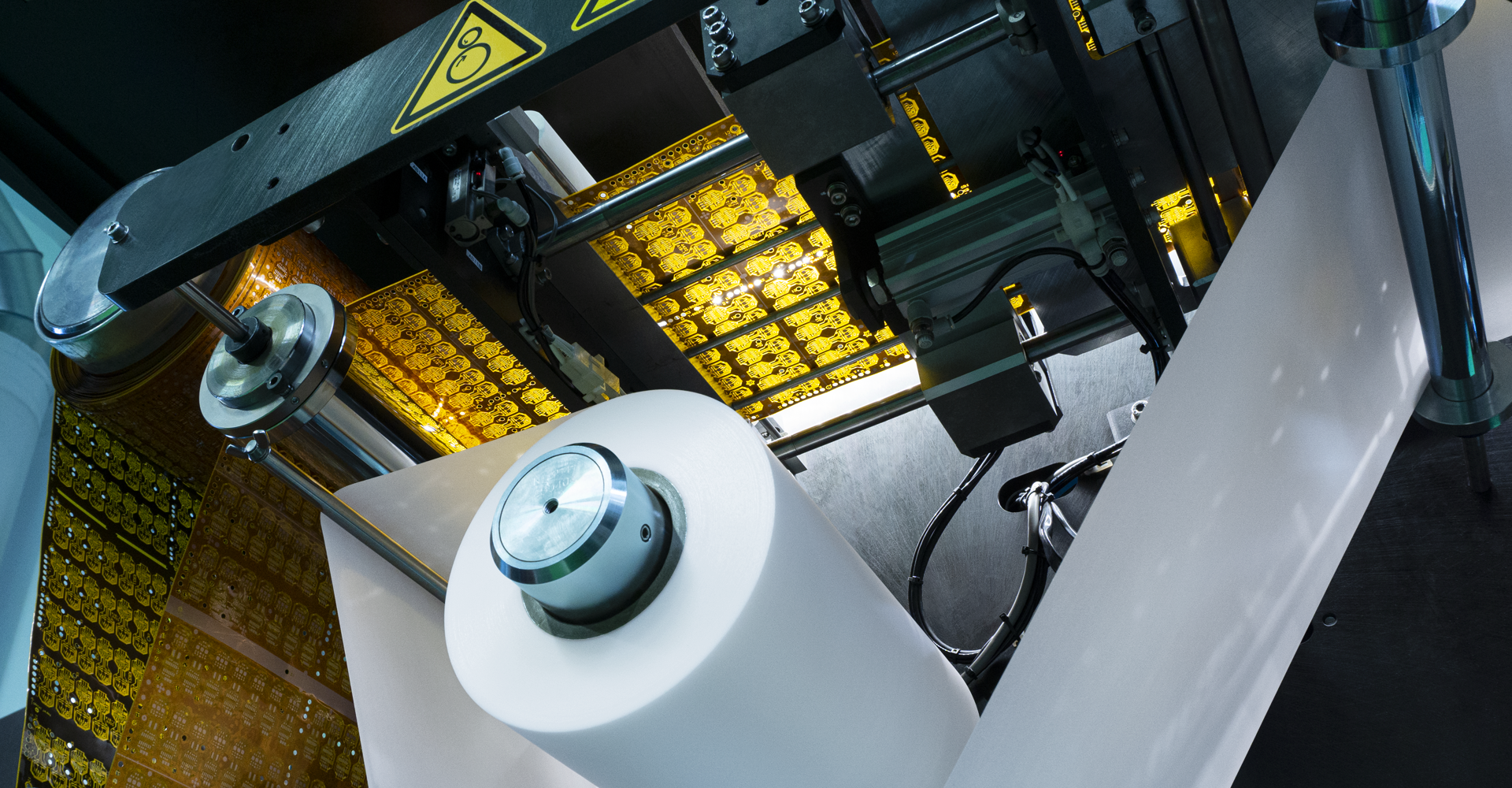

Mektec’s technology provides ultra-fine copper structures down to 30μm distance between two traces. To get a better idea: a human hair is twice as thick.

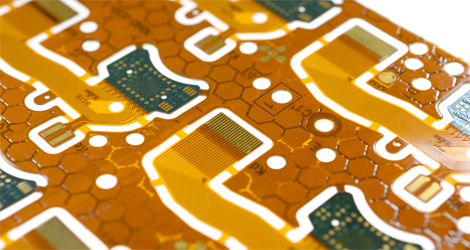

Please note that the shown Flexible Printed Circuit board demonstrates only about 70μm distance between two traces as it is difficult to compare our precise technology with everyday objects.