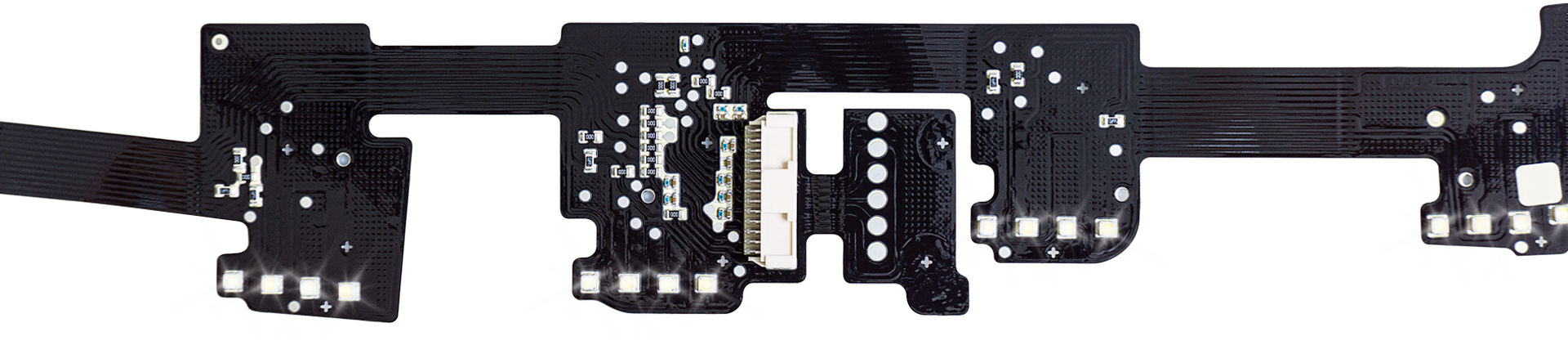

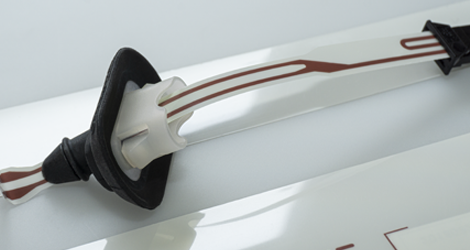

Crimp Connectors

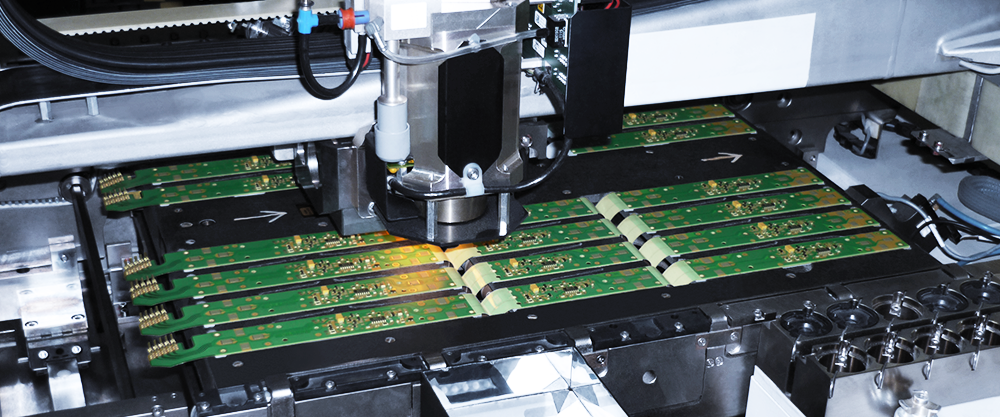

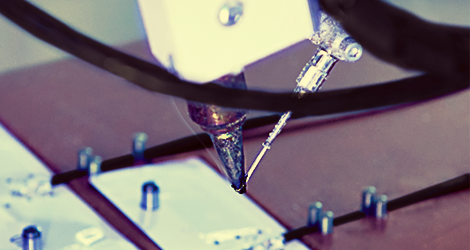

Interconnecting Mektec's Flexible Printed Circuits just like common round cables. Our crimping technology allows you to choose from a wide range of established connector systems that perfectly match your requirements. Supervised by our unique monitoring systems we crimp each terminal individually. All crimp contacts fulfill or even exceed highest automotive requirements (VDA AK guideline).